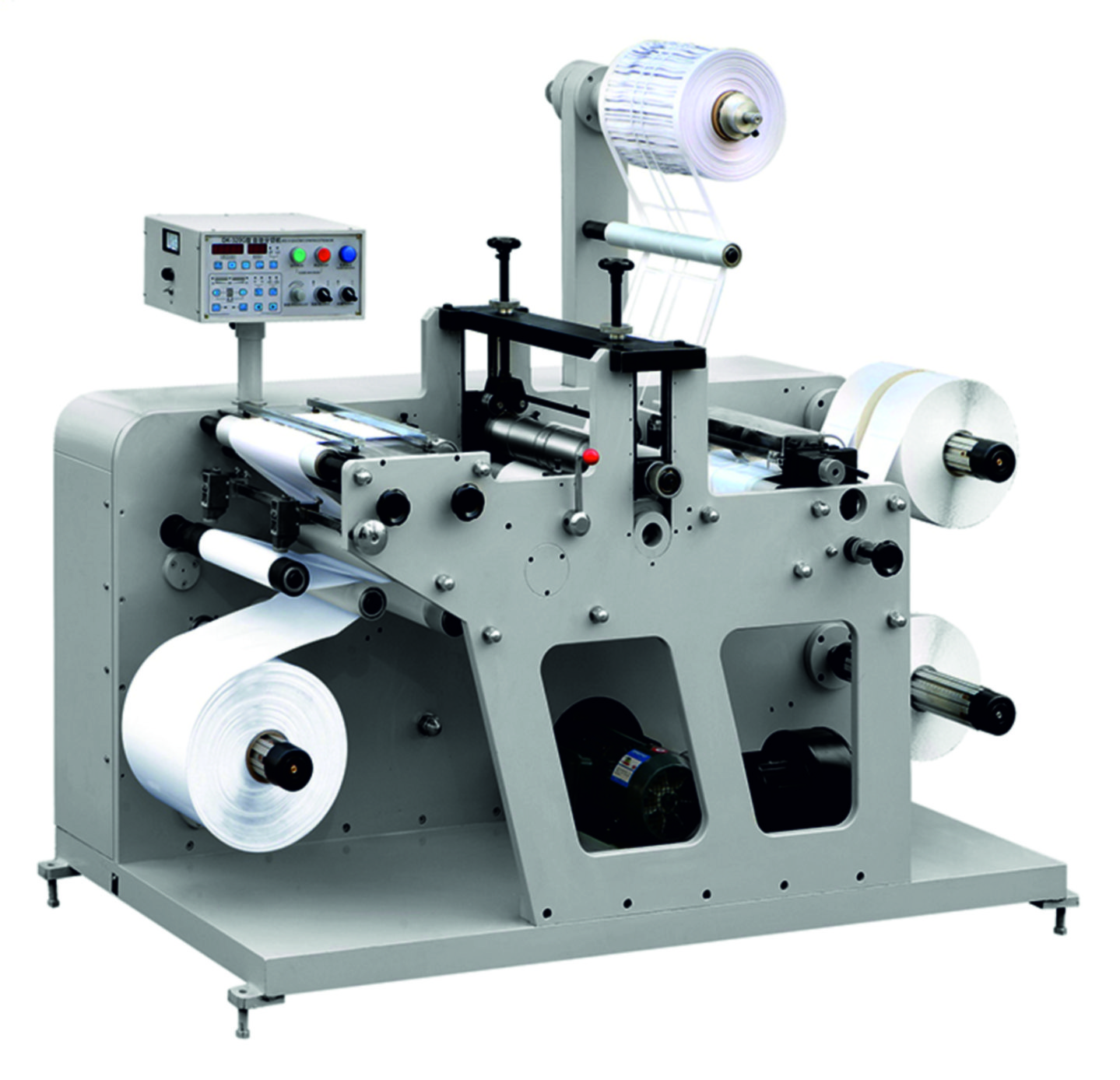

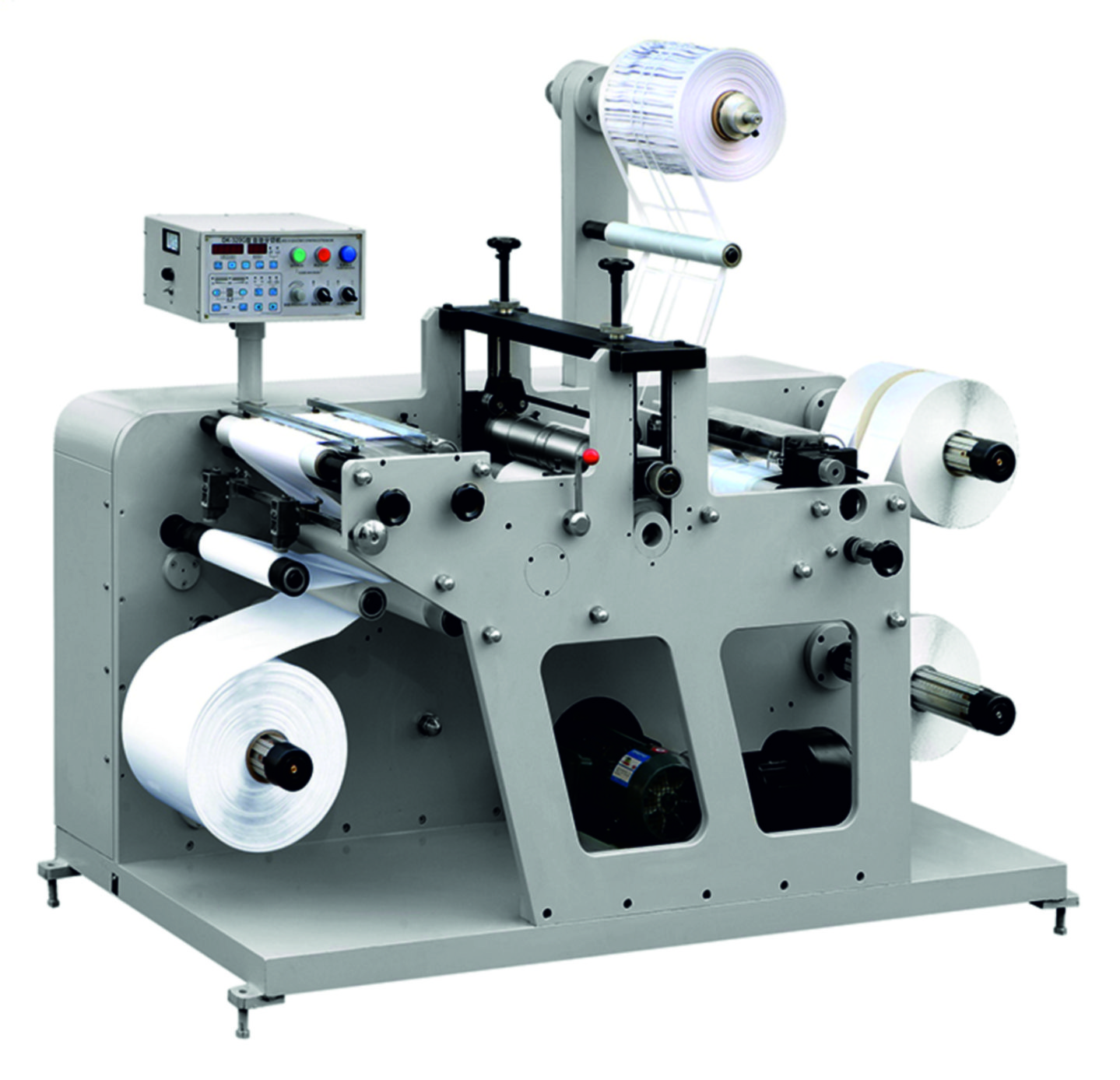

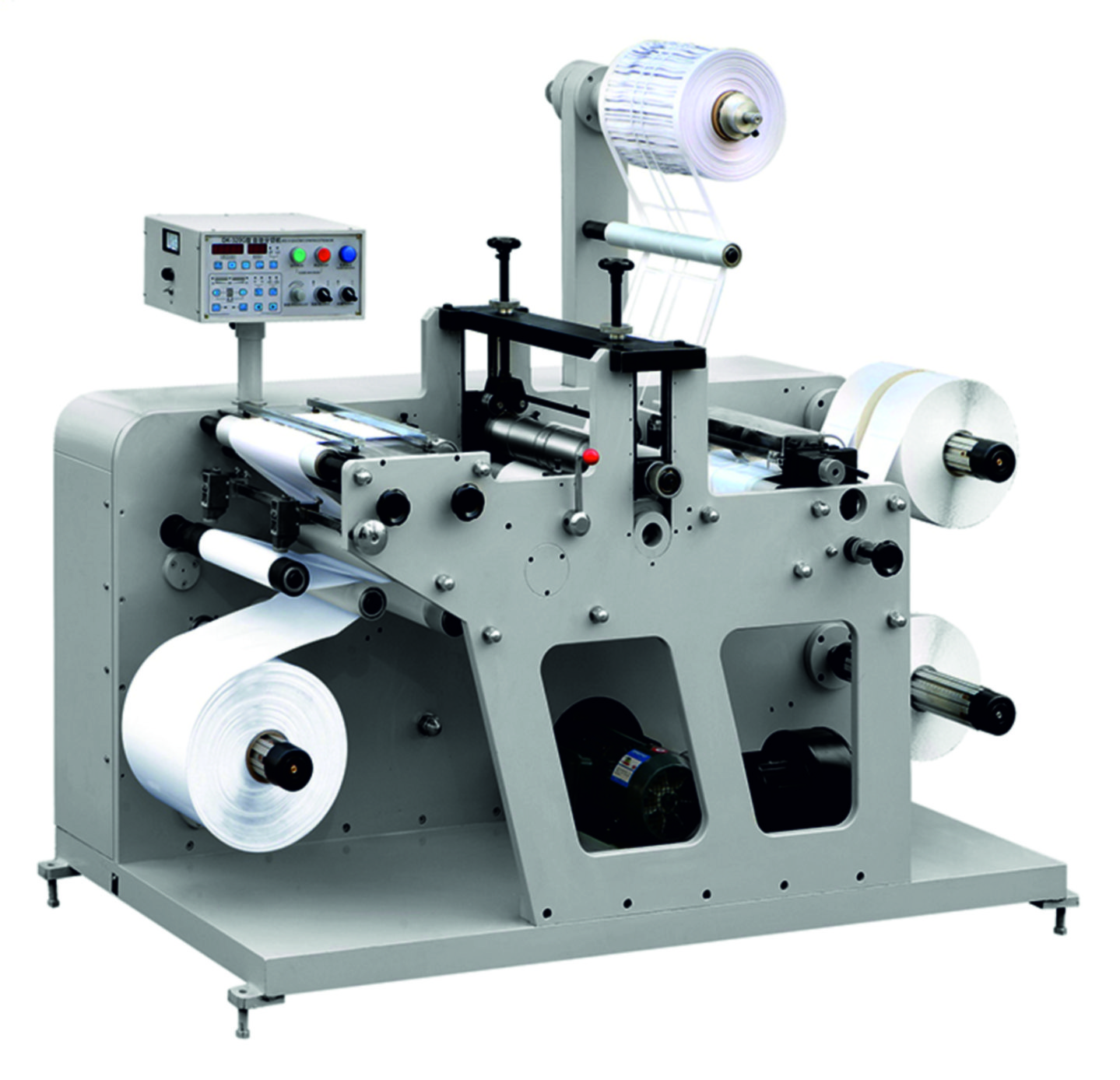

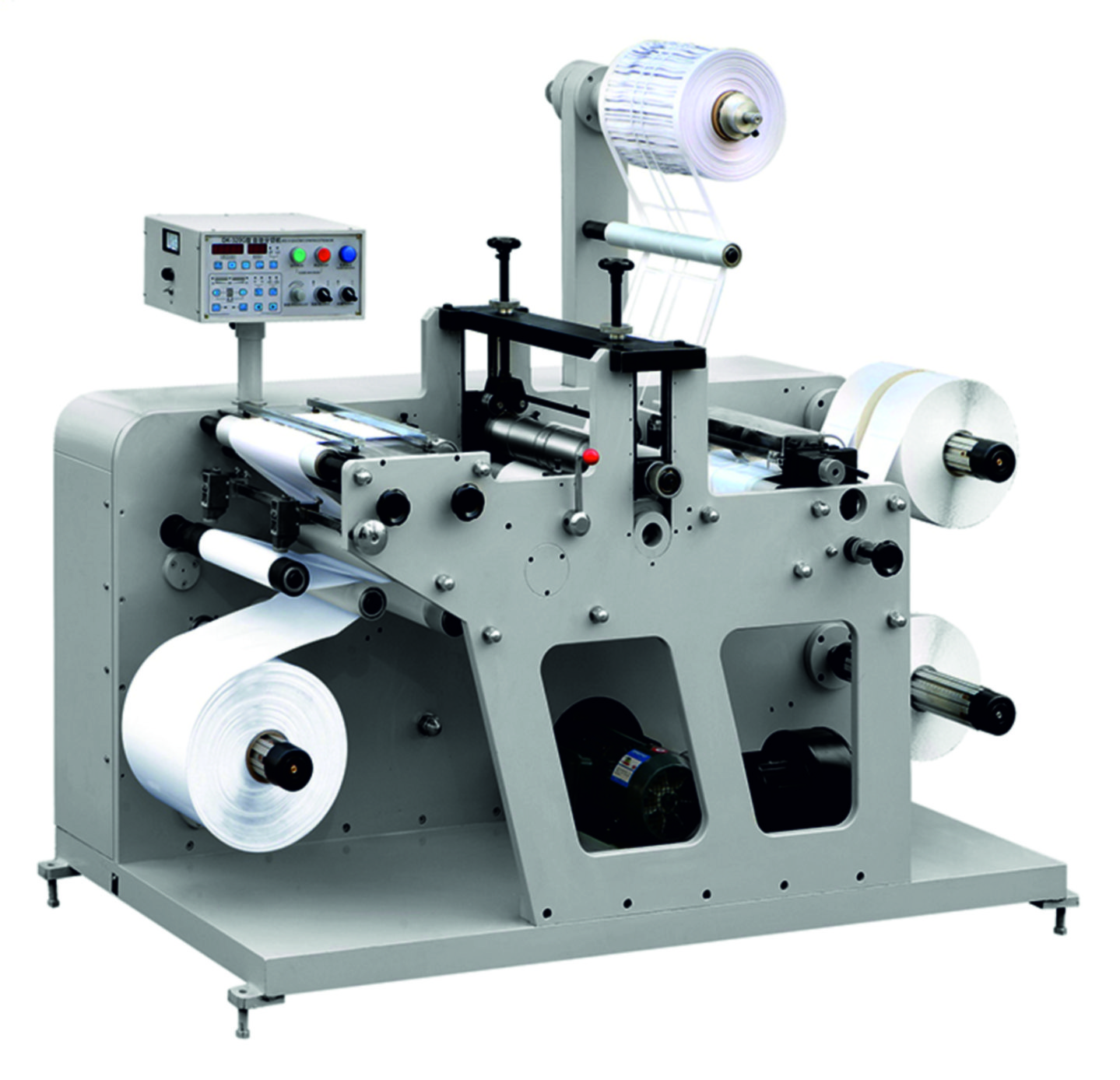

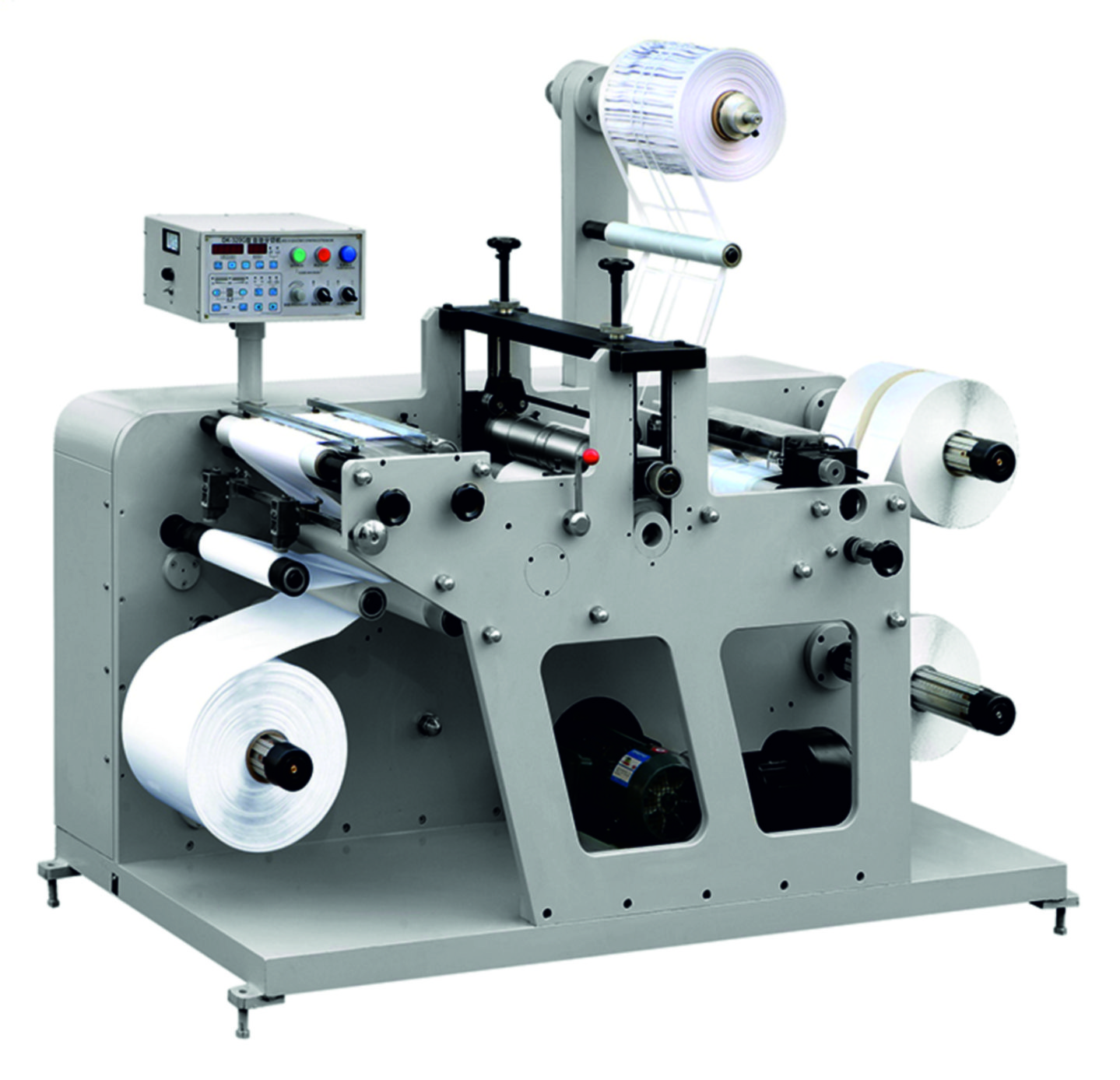

A Lable Sitting Machine is an essential device in the world of industrial printing and packaging. This machine plays a crucial role in applying lables accurately and efficiently to various products. It is typically used in industries such as food and beverage, pharmaceuticals, and consumer goods, where precise Lable placement is critical for branding, compliance, and product identification. The main purpose of a Lable Sitting Machine is to automate the process of affixing Lables to containers or products, ensuring uniformity and consistency. Unlike manual Lableing, which can be prone to errors and inefficiencies, these machines provide a streamlined solution that enhances production speed and accuracy. Lable Sitting Machines are designed with high precision to adhere Lables to a wide variety of surface shapes and materials, from cylindrical bottles to irregularly shaped containers. They are equipped with advanced features, such as sensor-based alignment systems, to ensure that each Lable is placed with high accuracy and minimal wastage.

Lable Sitting Machines come with a range of features that make them highly effective in industrial environments. Some of the key features include:

When considering a Lable Sitting Machine, it's essential to understand its technical specifications, as they directly influence its performance and suitability for different production environments. Here are some of the key specifications to look for:

The adoption of Lable Sitting Machines offers several benefits to businesses looking to streamline their production lines and improve their Lableing processes. These include:

Lable Sitting Machines are used across a wide range of industries. Some of the most common applications include:

When choosing a Lable Sitting Machine, it’s important to compare different models and technologies to find the one that best suits your needs. Below is a comparison of common types of Lable Sitting Machines:

Proper maintenance of a Lable Sitting Machine is critical to ensuring its longevity and optimal performance. Here are some maintenance tips:

The future of Lable Sitting Machines is marked by advancements in automation, connectivity, and smart technology. Some of the trends to watch include:

The Lable Sitting Machine is an invaluable tool for businesses in a wide range of industries. By automating the Lableing process, companies can significantly improve their production efficiency, Lable accuracy, and overall product presentation. With advancements in technology, these machines are becoming smarter, more flexible, and increasingly capable of meeting the demands of high-volume production lines. Whether you are looking to improve operational efficiency, reduce costs, or ensure compliance, investing in a Lable Sitting Machine is a step towards enhancing your business’s competitiveness in the marketplace.

Yes, U.V Graphic Technology Private Limited specializes in offering customized solutions to meet specific client requirements. Whether it's machine size, speed, or additional features, we tailor our products to suit your needs.

Yes, we offer tailored solutions to meet your specific production needs. From machine size to additional features, our team can design and manufacture machines as per your requirements.

Our flexographic printing machines can print on materials such as:

• Paper

• Plastic films (PE, PP, PET)

• Aluminum foil

• Laminates

• Corrugated sheets

Yes, our machines are designed to handle water-based, UV-curable, and solvent-free inks, making them suitable for eco-conscious businesses.